- Home

- About Us

- Students

- Academics

-

Faculty

- Electrical Engineering

- Automation

- Computer Science & Engineering

- Electronic Engineering

- Instrument Science and Engineering

- Micro-Nano Electronics

- School of Software

- Academy of Information Technology and Electrical Engineering

- School of Cyber Security

- Electrical and Electronic Experimental Teaching Center

- Center for Advanced Electronic Materials and Devices

- Cooperative Medianet Innovation Center

- Alumni

-

Positions

-

Forum

News

- · Shanghai Jiao Tong University professors Lian Yong and Wang Guoxing's team have made remarkable progress in the field of high-efficiency pulse neural network accelerator chips.

- · AI + Urban Science research by AI Institute was selected as cover story in Nature Computational Science!

- · The first time in Asia! IPADS's Microkernel Operating System Research Wins the Best Paper Award at SOSP 2023

- · Delegation from the Institution of Engineering and Technology Visits the School of Electronic Information and Electrical Engineering for Journal Collaboration

- · Associate professor Liangjun Lu and research fellow Jiangbing Du from Shanghai Jiao Tong University made important advancements on large capacity and low power consumption data transmission

Associate Researcher Guo Gao and co-workers prepared MOF-derived porous TiO2/ZnO/C@CNTs composites to enhance lithium storage performance

Recently, Associate Researcher Guo Gao and co-workers from the School of Sensing Science and Engineering, School of Electronic Information and Electrical Engineering published a research paper entitled “Porous MOF derived TiO2/ZnO/C@CNTs composites for enhancing lithium storage performance” in Chemical Engineering Journal. In this study, a porous TiO2/ZnO/C@CNTs composite derived from metal-organic frameworks (MOFs) was reported. Through the rational design of its morphology and composition, the composite achieved good cycling performance and rate performance, showing the prospect of it being used as anode materials for lithium-ion batteries.

Metal-organic frameworks (MOFs) have been widely studied in the field of anode materials for lithium-ion batteries in recent years because of their intrinsic porous structure, ultra-high specific surface area, and abundant active sites. However, the practical application of MOFs is severely limited by their low electrical conductivity and poor chemical stability. Pyrolysis of MOFs under appropriate conditions can obtain MO/C composites containing metal oxide (MO) and carbon layer while maintaining the skeleton structure of MOFs, which is one of the effective methods to improve the electrochemical lithium storage performance of MOFs.

In this study, the performance of porous TiO2/ZnO/C@CNTs was optimized by first constructing dual MOFs composites.

1. Rationally designed double MOF composite material can combine the advantages of two independent MOFs materials. Two kinds of MOFs (MIL-125 and ZIF-8) were isomerized by functional group control to obtain a homogeneous dual MOF composite MIL-125/ZIF-8.

2. MIL-125/ZIF-8@CNTs composites were obtained by using multi-walled carbon nanotubes (CNTs) as a cross-linking agent to prevent ZIF-8 from falling off the surface of the composites. At the same time, CNTs can further improve the conductivity, stability, and porosity of the material.

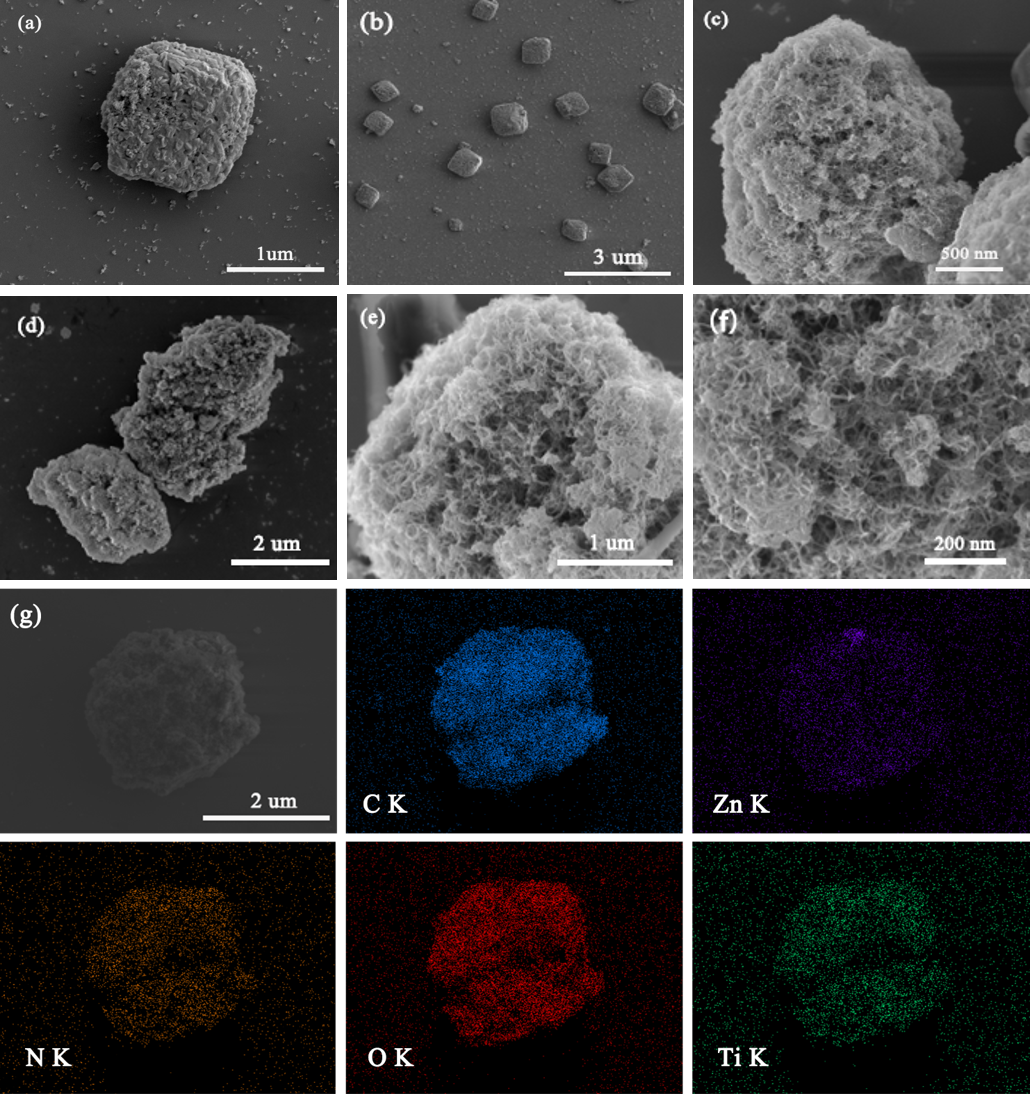

3. Porous TiO2/ZnO/C@CNTs composites were obtained by sintering MIL-125/ZIF-8@CNTs (Figure 1). After pyrolysis, MIL-125 was converted to TiO2/C, ZIF-8 was converted to ZnO/C, and CNTs were wrapped on the surface of TiO2/ZnO/C. (1) CNTs dispersed on the surface of the material can not only prevent ZIF-8-derived ZnO from falling off the surface of the material during cycling, but also improve the conductivity of the composite material, increase the stability of the structure, and alleviate the volume expansion of the material during charging and discharging. (2) In the process of sintering, abundant mesopores are formed due to gas overflow, and the abundant pore structure is conducive to the infiltration of electrolytes and can accommodate the volume change in the process of charging and discharging. (3) TiO2 derived from MIL-125 has good cycle stability, and ZnO derived from ZIF-8 has a high specific capacity, so the composite material has good comprehensive performance.

Figure 1 SEM images of the TiO2/ZnO/C@CNTs composites

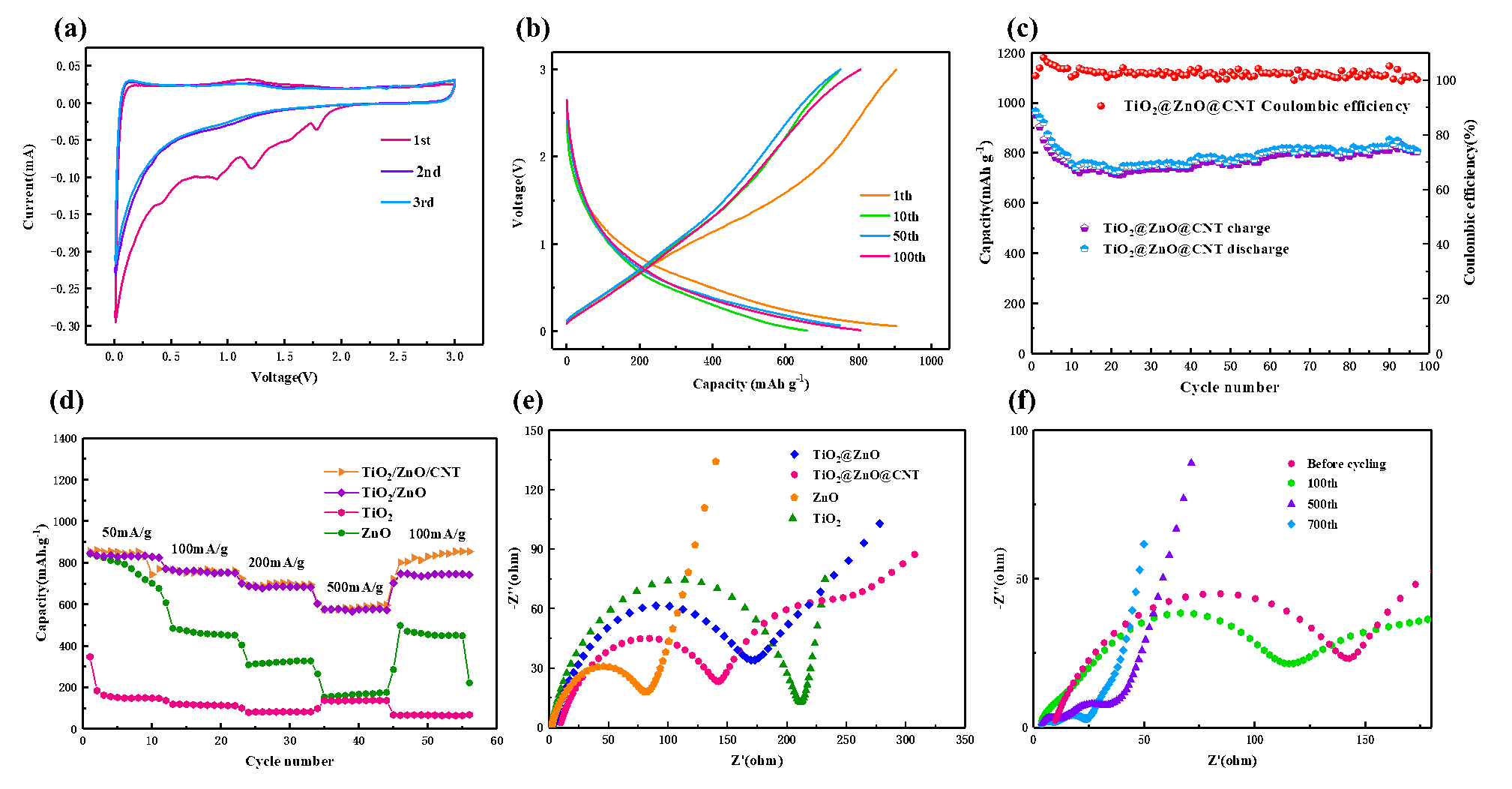

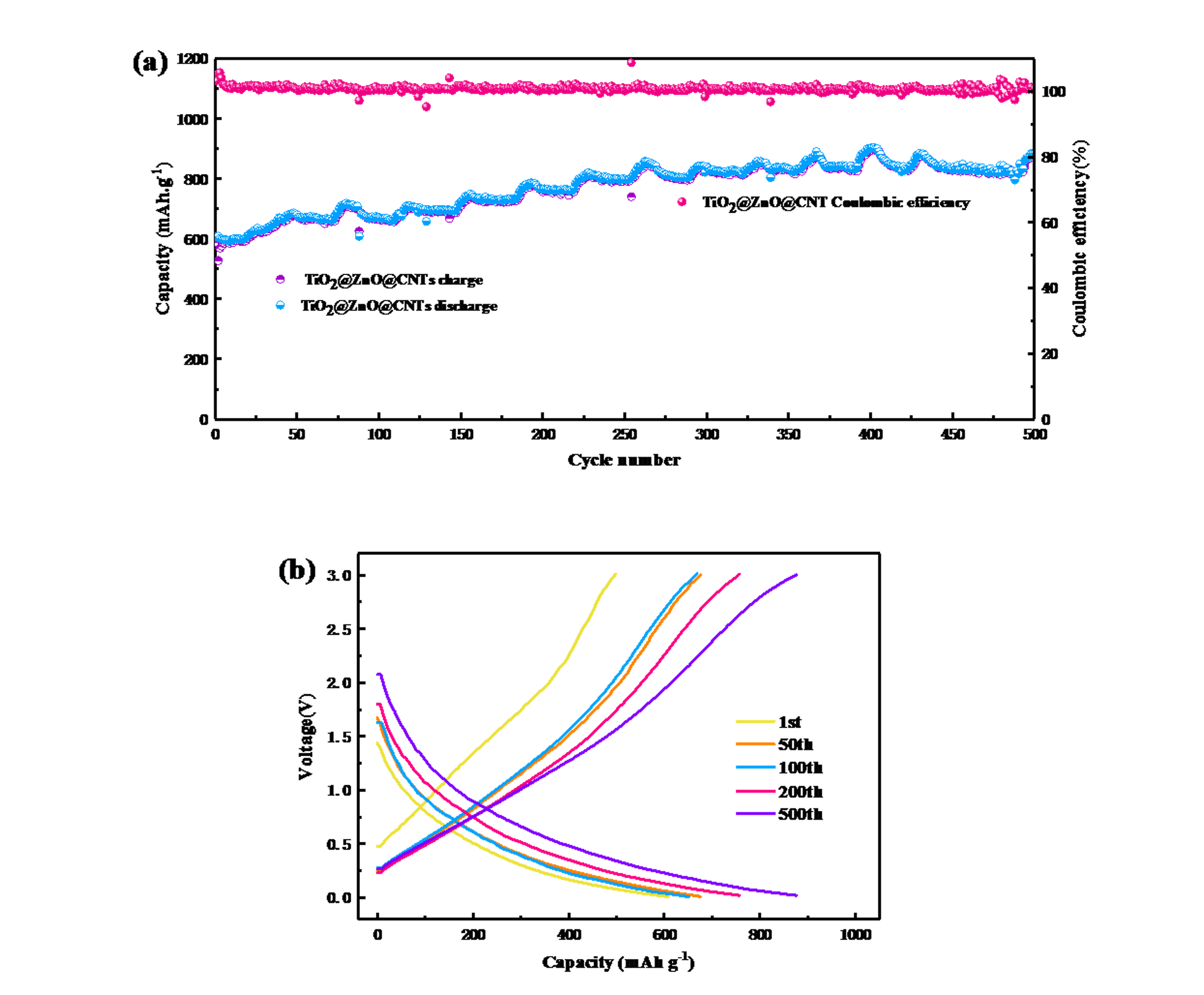

Electrochemical tests showed that the prepared porous TiO2/ZnO/C@CNTs had excellent lithium storage performance (Figure 2). The composites exhibited good cycling performance and rate performance: The capacity was 816.8 mAh g−1 after 100 cycles at the current density of 100 mA g−1, and the capacity could still reach more than 800 mAh g−1 even after 500 cycles at the high current density of 2 A g−1 (Figure 3).

Figure 2 Electrochemical properties of the TiO2/ZnO/C@CNTs composites

Figure 3 (a) Cycling performance and (b) discharge-charge curves of TiO2/ZnO/C@CNTs composites at 2 A g−1

Hui Cheng and Guiying Xu, master’s students at the School of Sensing Science and Engineering, School of Electronic Information and Electrical Engineering, Shanghai Jiao Tong University, are the co-first authors of the paper, and Associate Researcher Guo Gao is the corresponding author. This work was supported by the National Natural Science Foundation of China (81671737) and the Interdisciplinary Program of Shanghai Jiao Tong University (YG2021QN102, YG2021QN65, YG2019QNB31).

Paper link: https://doi.org/10.1016/j.cej.2022.140454

-

Students

-

Faculty/Staff

-

Alumni

-

Vistors

-

Quick Links